Cold Storage Lighting

The main purpose of cold storage is to maintain the quality of the product and extend its useful life. Due to their low temperatures, high humidity, and freezing temperatures that may reach -30°C, and limited windows and exits to ensure cooling effectiveness, the requirements for lighting in cold rooms are different from those in other locations. Products such as food and pharmaceuticals are usually stored on high shelves and personnel do not enter cold rooms frequently unless required. Taking these factors into consideration, cold storage lighting must meet the following conditions:

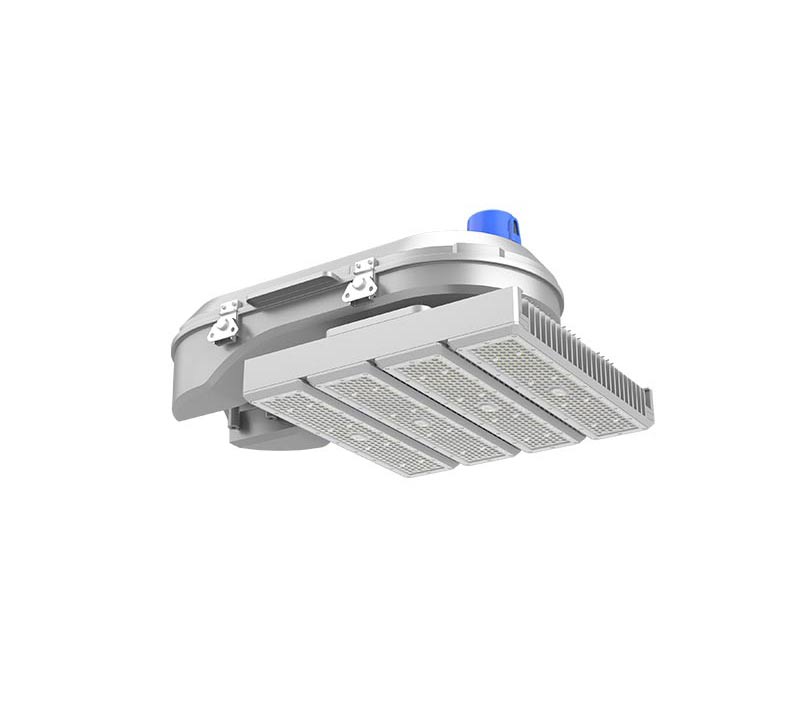

- can work stably in a -30℃ environment with low maintenance cost and high protection level.

- low heat generation to avoid aggravating the burden of the cooling system. In elevated environments, narrow and long lighting patterns should be selected to ensure that light is maximized and wastage is avoided. Moreover, forklift drivers must be able to clearly see the upper and lower positions of shelves and products, which requires that the lighting be able to ensure the horizontal and vertical visual comfort of the human eye, thus improving work safety and efficiency.

- Considering the infrequent movement of people in and out of cold storage, the lighting system should be equipped with a variety of intelligent control options, which can effectively reduce operation and maintenance costs.