Key Fact Things You Need to Know About Shock Resistant Street Light Led

By Alice

Published On: January 1, 2024

Table of Contents

- 1. What is Shock Resistant Street Light Led?

- 2. Why Street Light Led needs Shock Resistant?

- 3. The advantages of Street Light Led Shock Resistant

- 4. How to ensure that LED street lights are vibration resistant?

- 5. How to prove led street light Shock Resistant?

- 6. Which street lights from MKLIGHTS are shock resistant?

Recently, we noticed a large-scale LED street light failure in Wellington, New Zealand. The city reportedly needs to pay NZ$6 million to repair and replace approximately 17,000 LED streetlights that tend to fall. The incident was the result of local and central governments focusing too much on price while neglecting quality and durability during the procurement process. You can find more information about this incident in the article <Flawed procurement practices to blame for faulty Wellington streetlights>.

These failures that occurred in Wellington show that if LED street lights do not have sufficient resistance to vibration, the lamps may fall if there is a slight vibration, which will cause serious safety hazards. As an LED street light supplier with 15 years of experience, we deeply feel that this is a serious quality accident. We hope to provide customers with professional advice to help them avoid problems like the one in Wellington when purchasing shock resistant LED street lights.

1. What is Shock Resistant Street Light Led?

The “Shock Resistant Street Light Led” is an LED street light designed to resist the effects of vibration. In certain environments, such as bridges, elevated roads, tunnels or earthquake-prone areas, vibrations may cause damage or shorten the life of the street light. Therefore, there is a need for specially designed vibration-resistant LED street lights that can last and work under these conditions. Due to its anti-vibration performance, this LED street light is widely used in a variety of lighting solutions for demanding environments, including but not limited to city streets, highways, bridges, tunnels, construction sites and other locations.

2. Why Street Light Led needs Shock Resistant?

There are several key reasons why LED street lights need to be shock-resistant:

- LED street lamps are typically installed on both sides of the road. In the event of traffic accidents, high-speed cars can collide with lamp posts, causing them to vibrate at high frequency. If the LED street lamps are not sufficiently shock-resistant, the fixtures are likely to be damaged and fall, potentially causing secondary injuries to pedestrians. Therefore, the shock resistance of LED street lights is very important.

- Vibration could affect the electronic components: LED street lights contain numerous electronic components, such as LED chips, driver circuits, and surge protectors. These components could be affected by vibration, resulting in disconnections, unstable operation or damage.

- Vibration could cause LED street light tilt shift: strong vibration may cause the luminous surface of LED street lights to lose its horizontal orientation, affecting light distribution and overall lighting effect.

- Vibration could shorten the lifespan of the lamps: even if vibration does not cause immediate damage to the lamps, it may accelerate the wear and tear of the lamps, thereby shortening their lifespan.

The effects of vibration are particularly significant in special environments such as bridges, elevated roads, tunnels, and earthquake-prone areas. Therefore, lighting fixtures in these areas often require a vibration-resistant design.

3. The advantages of Street Light Led Shock Resistant

The shock resistance of LED street lights has a significant impact on their effectiveness and longevity. Here are some of the main benefits:

- Long life: anti-vibration design can protect the internal components of the LED street light from vibration, which can reduce the damage of the components, thus prolonging the service life of the LED street light.

- Improve stability: anti-vibration design can make the LED street light still work stably under the vibration environment, for example, in the case of wind blowing, traffic impact or earthquake, the position and angle of the light will not change, which ensures the stability of the lighting.

- Reduced maintenance costs: As the anti-vibration design reduces damage caused by vibration, this means less maintenance and replacement is required, thus saving the associated maintenance costs.

- Improved safety: Strong vibrations can cause luminaires to fall or break, creating safety issues. A vibration-proof design can greatly reduce this risk.

Wider application: Due to the anti-vibration performance, LED street lights can be used in more environments, such as bridges, tunnels, and earthquake-prone areas.

Therefore, it is of great significance to carry out anti-seismic design for LED street lamps, whether it is from the aspect of improving the service life of the product, improving the stability of lighting, reducing the maintenance cost, improving the safety, or expanding the scope of application, and so on.

4. How to ensure that LED street lights are vibration resistant?

There are several strategies to ensure the anti-vibration performance of LED street lights during design and manufacturing:

- Choose high-quality materials: The housing and internal structure of the luminaire should be made of high-quality materials that can withstand a variety of environmental impacts, including vibration. For instance, all MKLIGHTS LED street lights are made of ADC12 aluminum alloy, which can effectively reduce the impact of vibration on the device.

- Utilize a well-designed structure: The structural design of the luminaire should account for anti-vibration. For example, if the mounting handle of the LED street light is a part of the main body of the luminaire, such as in MKLIGHTS’s SD1, SD2, and SI series of street lights, rather than being screw-fixed later, the structure is most suitable for anti-vibration.

- Select high-quality LED chips: High-quality LED chips are more resistant to vibration and pressure. Some low-quality LEDs may be more susceptible to damage under vibration.

- Luminaire installation: When installing luminaires, ensure they are firmly fixed to the pole to minimize vibration. Devices such as anti-vibration pads, fasteners, and springs can be used to further increase their stability.

- Ensure stable circuit design: The driver power supply should be firmly screwed to the housing and tightly bonded with it to prevent circuit failure due to vibration.

- Design anti-vibration packaging: As most MKLIGHTS lamps are exported and need to be transported over long distances, the packaging design incorporates thick pearl cotton foam to wrap the lamps and prevent any damage due to vibration during transportation.

The above are some ways to ensure the anti-vibration properties of LED street lights, but specific measures may vary according to different application environments and design needs.

5. How to prove led street light Shock Resistant?

The anti-vibration properties of LED street lamps are mainly proven through various vibration tests. The most commonly applied laboratory test standards for LED lamps presently are IEC 60068-2-6 and ANSI C136.31-2010.

IEC 60068-2-6 and ANSI C136.31-2010 are both vibration test standards but they differ in their applications, test parameters, and requirements.

IEC 60068-2-6 is an environmental test standard developed by the International Electrotechnical Commission (IEC). It is a generalized vibration test standard applicable to a wide range of electronic and electrical products. It covers both fixed-frequency and variable-frequency sine-wave vibration testing and can be used to simulate the vibrations that a product may encounter during transportation and usage.

ANSI C136.31-2010, on the other hand, is a vibration testing standard developed by the American National Standards Institute (ANSI) specifically for highway and area lighting equipment, such as streetlights. It comprehensively defines the process and requirements for vibration testing, including testing on three orthogonal axes (X, Y, and Z) with frequencies typically ranging from 4 to 33 Hz and a vibration duration of at least four hours on each axis.

Overall, while IEC 60068-2-6 focuses on general-purpose environmental vibration testing, ANSI C136.31-2010 is more specific to vibration testing of highway and area lighting equipment. The choice of which standard to use for testing may vary depending on the specific application and needs of the product.

As a professional supplier of LED street lights, the majority of MKLIGHTS’ street lights have passed both IEC 60068-2-6 and ANSI C136.31-2010 vibration tests, meeting most of the requirements for highway and area lighting. Please contact our sales specialists for further information.

6. Which street lights from MKLIGHTS are shock resistant?

Offering professionally customized LED street lights for demanding environments such as bridges, tunnels, and construction sites is a rare feat among LED road lighting companies. MKLIGHTS, however, does not forsake research and development due to low demand. We are always committed to helping our customers solve their lighting-related challenges.

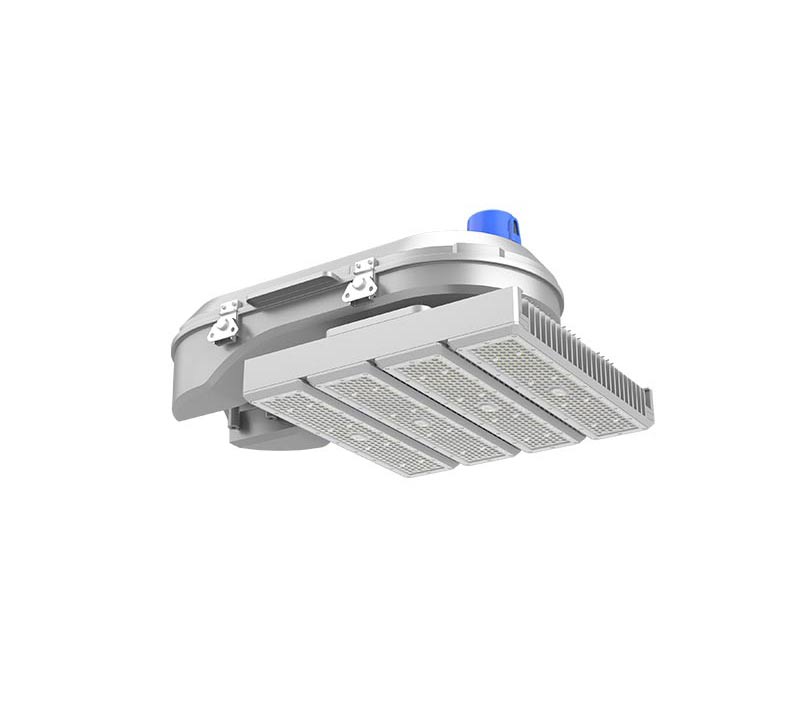

Currently, most LED street lights in the MKLIGHTS series meet the basic 3G anti-vibration capability. Those with the best anti-vibration capabilities mainly include the following products:

If you have any questions or needs regarding anti-vibration, please feel free to contact our sales specialists. We will provide you with a comprehensive solution.

Author

Alice

Lighting Specialist

As a sales engineer at MK Lighting, I have been in the LED lights industry for more than 13 years. Good at lighting design, light system configuration, and bidding technology support. Feel free to contact us. I’m happy to provide you with the best service and products.

Related Products

How Can We Help You?